The History of Real Stone Veneer

Sawn thin stone veneer is a relatively recent innovation. Particularly when you consider the origins of stone as a building material. From the ancient pyramids in Egypt to Stonehenge, humans have been building with stone for centuries. Even as building techniques advanced and civilizations modernized, most of the stone used for building was still limited to heavy, thick stones. New technologies for cutting and shaping stone didn’t start to emerge until the mid-20th century.

In this post, we explore the history of building with stone and how today’s natural stone veneer is creating opportunities to enjoy the beauty of natural stone without significant weight and structural concerns.

Stone, the Foundation of Human Civilization

Building with stone is a practice that dates back to the dawn of civilization. Stone structures, ranging from the humble huts of our ancient ancestors to monumental constructions such as the pyramids of Egypt, the Parthenon in Greece, and the great Wall of China, bear testimony to mankind’s early ingenuity.

Initially, stones were used in their natural form, merely stacked upon one another to create rudimentary shelters. Over time, as tools and techniques advanced, stones began to be shaped, chiseled, and arranged in more complex ways, leading to the architectural marvels that still stand today. Stone was, and still is, chosen for its durability, aesthetic appeal, and relative abundance, making it a core component of human construction throughout history.

The Birth of Stone Veneer

Stone veneer traces its origins back to the 19th century, when advancements in transport and construction technologies made it possible to extract and move large quantities of stone. Early stone veneers were relatively thick and heavy, limiting their application.

The primary purpose of using stone veneer was to replicate the appearance of solid stone construction at a fraction of the cost. This was achieved by cutting stones into thinner slices and applying them to the exterior of buildings. These early stone veneers had the aesthetic benefits of solid stone construction, and were slightly easier to work with than historical building stone.

Manufactured Stone Veneer Takes Off

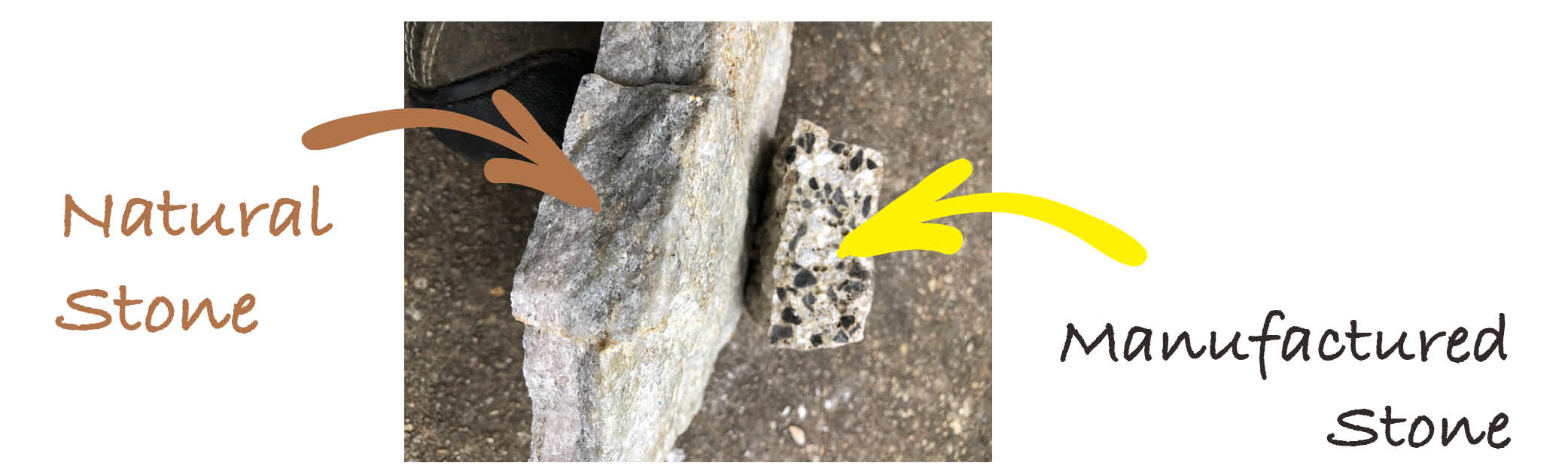

Capitalizing on the demand for the appearance of real stone, companies started manufacturing stone veneer, also referred to as faux stone or cultured stone. Architects and designers quickly began utilizing these products to to overcome the limitations posed by natural stone – high cost, weight, and the need for skilled masonry.

The process of making manufactured stone veneer involves a mixture of cement, aggregates, and iron-oxide pigments poured into moulds that replicate the texture and color of natural stone. The result is a lightweight, durable product that mimics the look of natural stone at a fraction of the cost and weight.

Its ability to be mass-produced and the flexibility in design, color, and texture, propelled manufactured stone veneer into popularity. Homeowners, architects, and designers embraced it for its aesthetic appeal, affordability, and easy installation. It can be used in a variety of applications, both interior and exterior, from fireplaces and accent walls to exterior home siding and landscaping projects.

Learn More About Real vs. Manufactured Stone Veneer:

Over the years, manufacturing processes have continued to improve, offering even more realistic representations of natural stone. However, it’s important to note that while manufactured stone veneer provides certain advantages, it doesn’t quite match the authenticity, longevity, and unique character of natural stone or real stone veneer.

Sawn Thin Natural Stone Veneer: The Modern Innovation

While manufactured stone veneer has its place in the market, it fails to deliver authenticity, durability, and timeless elegance. Designers, architects, builders, and masons were desperate for a better solution.

As stone cutting technology continued to evolve, companies were able to achieve greater precision and consistency with their cuts. Today’s sawn thin natural stone veneer is often less than an inch thick and can be cut from almost any type of stone. This makes it possible to offer a wide variety of colors, textures, and finishes.

Natural Facing’s Chesapeake Roughly Rectangular installed in at a corporate plaza in Northern Virginia.

Sawn thin stone veneers have become increasingly popular due to their versatility, lightness, and ease of installation. Unlike earlier versions of stone veneer, these thin slices can be applied to a range of substrates and are suitable for both interior and exterior applications.

Crafting Beauty: The Process of Cutting Stone Veneer

Real stone veneer is a product of both traditional craftsmanship and modern engineering. The process begins at the quarry, where large slabs of natural stone are carefully extracted. These slabs are then transported to a processing facility.

Once there, the slabs are cut into manageable sizes, usually with the aid of diamond-tipped saws to ensure precise cuts. Then, these smaller blocks are sliced into even thinner pieces, typically less than an inch thick, to form the veneer. The slicing must be done carefully to preserve the natural coloring and texture of the stone.

For a more rustic or natural look, the edges of the veneer can be chiseled or snapped. For a more contemporary or clean look, the edges can be saw-cut. The backside of the veneer is often processed to ensure a flat surface for better adhesion when installed. This careful cutting process allows for the creation of a lightweight, versatile product that retains the beauty and durability of solid stone, making real stone veneer an attractive choice for a variety of architectural and design applications.

Natural vs Manufactured: The Superiority of Real Stone Veneer

When it comes to choosing between natural and manufactured stone veneer, the timeless appeal and superior qualities of real stone veneer often take center stage. Real stone veneer, being a product of nature, boasts a unique authenticity that manufactured stone can’t quite replicate. Each piece of real stone veneer is distinct, exhibiting unique patterns, textures, and color variations. In terms of durability, real stone veneer outshines its manufactured counterpart, capable of withstanding the elements and aging beautifully over time. It also contributes to the property’s value, as structures adorned with natural stone are often seen as premium investments. Environmentally speaking, the production of real stone veneer tends to be more eco-friendly than manufactured stone, considering the non-renewable resources used in the latter’s production. Additionally, the maintenance and repair of real stone veneer are often less burdensome than manufactured stone, making it a preferred choice for many designers and architects. These factors underpin the superiority of real stone veneer in the natural versus manufactured debate.

The photos below are Natural Facing Autumn Crest Mosaic Stone Veneer. Browse additional real stone veneer projects featuring Natural Facing.

Authenticity & Uniqueness

Real stone veneer is exactly that – real stone. It has an authenticity that simply cannot be fully replicated by manufactured alternatives. Each piece of real stone veneer has its own unique texture, color, and pattern, adding an element of uniqueness and depth to designs that is unmatched by manufactured stone.

Natural Stone’s Durability

Natural stone is known for its durability. Real stone veneer, despite being thin, retains this inherent durability. It can withstand the elements better than manufactured stone, and tends to age better, often gaining a desirable patina over time.

Maintenance and Repair

Real stone veneer generally requires less maintenance than its manufactured counterpart. Natural stone’s color permeates throughout, which means that any scratches, chips, or wear that occur over time are less noticeable. Once manufactured stone is damaged, matching or repairing can be extremely difficult, especially if the original product line has been discontinued or altered.

Environmentally-Friendly

Natural stone is essentially a ‘green’ material, given its abundant availability and the minimal processing it undergoes. Manufactured stone, on the other hand, requires significant energy inputs in its production and is made using non-renewable resources.

Design Versaility

While manufactured stone has made great strides in mimicking natural stone, the range of colors, textures, and finishes available in real stone veneer is vast. This diversity offers designers and architects a wide spectrum of choices to meet their design vision.

The Value of Real Stone

Buildings clad in real stone veneer can command higher prices, as buyers value the aesthetic appeal and longevity of natural stone. Real stone veneer can be seen as an investment that can increase a property’s value over time.

The Future of Natural Stone Veneer

The journey from the first monoliths to the sleek, thin veneers we see today is a testament to human ingenuity and the enduring appeal of natural stone. The history of stone veneer is a story of continuous innovation, always pushing for more efficient ways to use this timeless material.

As we gaze into the future of real stone veneer, it is evident that this age-old material will continue to play a significant role in the world of design and construction. Technological advancements will further refine the extraction and cutting processes, producing thinner and lighter veneers, and expanding their potential applications. Customizable shapes, sizes, and finishes will become even more prevalent, catering to increasingly diverse and sophisticated design tastes.

Moreover, as sustainability and environmental responsibility become more pressing, the appeal of real stone veneer – a natural, durable, and recyclable material – is likely to rise. Its unique blend of tradition, durability, and versatility ensures that real stone veneer will remain a favored choice among designers and architects for generations to come.

The possibilities for the application of natural stone veneer seem endless, and we can’t wait to see where this journey takes us next.

About Natural Facing Real Stone Veneer

From ordering, delivery, and installation to enjoying the finished product for decades to come, Natural Facing is the leading supplier for real stone veneer in the Mid-Atlantic. Our stone experts understand the nuances of real stone and work tirelessly to provide quality products and exceptional customer service.

Those who invest in Natural Facing understand the value of real stone veneer. And once they choose Natural Facing, they keep coming back. Our real stone veneer quality, longevity, and timeless beauty can’t be manufactured.